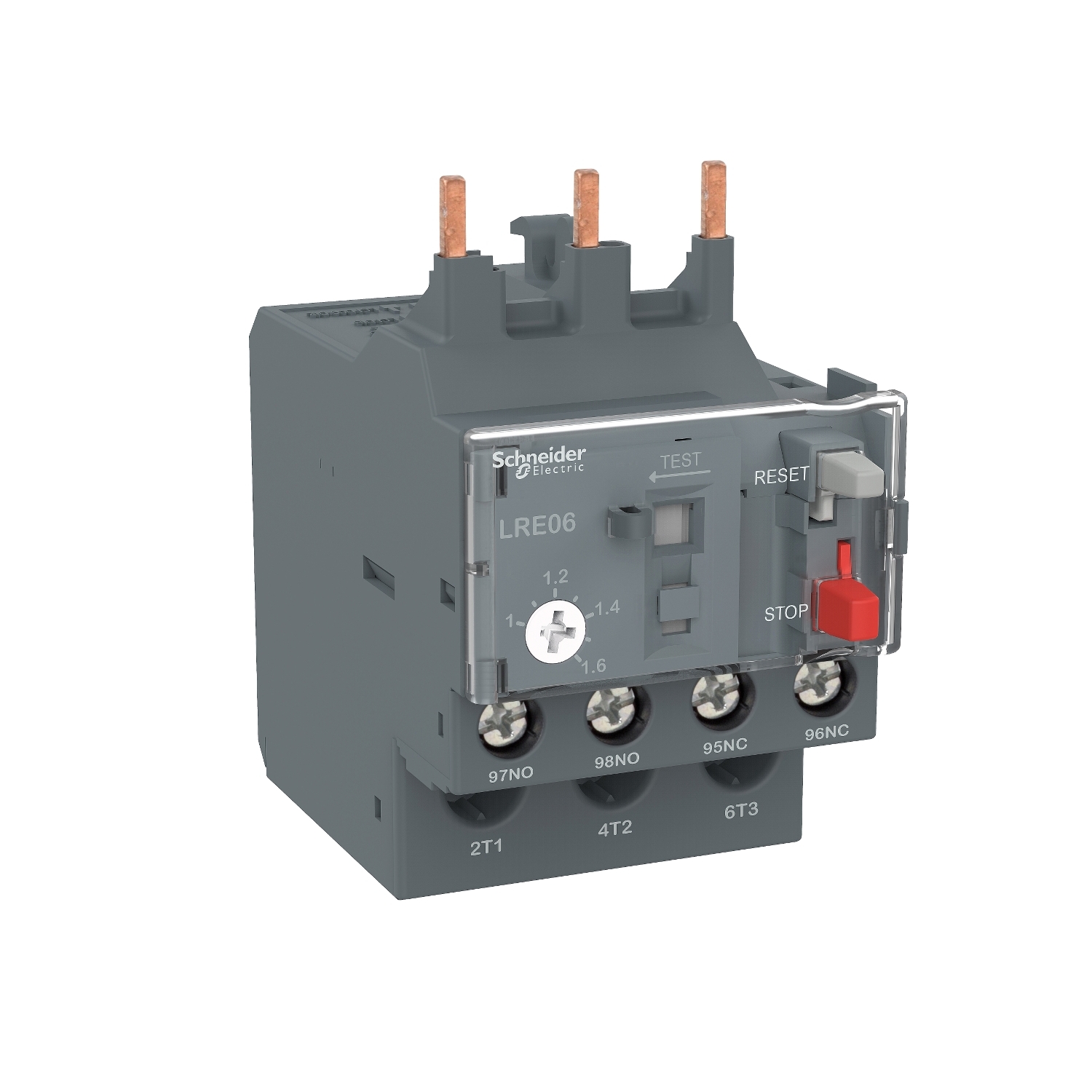

Schneider LRE32 | Thermal overload relay,EasyPact TVS,23…32A,for LRE01…E35,class 10A

1,425 EGP2,638 EGP (-46%)

Schneider LRE32| Thermal overload relay,EasyPact TVS,23…32A,for LRE01…E35,class 10A

n

n

n

Schneider LRE32 Description

n

Overview of Schneider Electric

n

History of Schneider Electric

n

Schneider Electric is a global leader in energy management and automation, with a history dating back to 1836. Over the years, they have evolved from a steel manufacturer to a key player in industrial automation, focusing on efficiency and sustainability.

n

n

Core Products and Services

n

Schneider Electric offers a broad range of products, from simple electrical components to complex automation systems. Their portfolio includes circuit breakers, sensors, switches, and programmable logic controllers (PLCs), all designed to enhance industrial operations.

n

n

Understanding the LRE32

n

General Features

n

The Schneider LRE32 is a thermal overload relay designed to protect electrical motors from overload and phase failure. It’s known for its robustness and reliability, ensuring that motors operate safely and efficiently.

n

n

Specifications and Technical Details

n

-

n

- Voltage: 690V

- Current Range: 0.1 to 32A

- Operating Temperature: -20°C to +60°C

- Mounting: DIN rail or screw mounting

n

n

n

n

n

Key Features of LRE32

n

Digital Display

n

One of the standout features of the LRE32 is its digital display, which provides real-time monitoring and easy-to-read diagnostics, simplifying the troubleshooting process.

n

n

Programmable Settings

n

The LRE32 offers programmable settings, allowing users to customize its operation according to specific needs. This flexibility makes it suitable for a wide range of applications.

n

n

Compact Design

n

Despite its powerful capabilities, the LRE32 boasts a compact design, making it easy to integrate into existing systems without requiring significant space.

n

n

Applications of Schneider LRE32

n

Industries Using LRE32

n

The LRE32 is widely used in various industries, including manufacturing, mining, and energy. Its reliability makes it a preferred choice for operations that demand consistent performance.

n

n

Typical Applications in Automation

n

In industrial automation, the LRE32 protects motors in conveyor systems, pumps, fans, and other critical machinery, ensuring minimal downtime and maximizing productivity.

n

n

Installation Process

n

Pre-Installation Requirements

n

Before installing the LRE32, ensure you have the necessary tools and that the environment meets the specified conditions, such as temperature and humidity levels.

n

n

Step-by-Step Installation Guide

n

-

n

- Turn off power: Ensure the power is completely off to avoid electrical hazards.

- Mount the relay: Install the LRE32 on a DIN rail or use screws for secure mounting.

- Connect wires: Follow the wiring diagram to connect the relay to the motor and control circuit.

- Configure settings: Use the digital display to set the desired parameters.

- Test the system: Turn on the power and test the relay to ensure it operates correctly.

n

n

n

n

n

n

Programming the LRE32

n

User Interface Overview

n

The user interface of the LRE32 is intuitive, featuring a digital display and a set of buttons for navigation and setting adjustments. The menu is straightforward, allowing quick access to various settings.

n

n

Common Programming Tasks

n

-

n

- Setting current range: Adjust the current settings based on the motor specifications.

- Configuring delay times: Set the appropriate delay times to prevent nuisance tripping.

- Testing the relay: Use the test function to simulate conditions and verify the relay’s response.

n

n

n

n

Benefits of Using Schneider LRE32

n

Enhanced Efficiency

n

The LRE32 improves motor efficiency by providing accurate protection and reducing unnecessary downtime, which can lead to significant cost savings in the long run.

n

n

Reliability and Durability

n

Designed for harsh industrial environments, the LRE32 is built to last, offering reliable performance and reducing the need for frequent replacements.

n

n

Comparing LRE32 with Competitors

n

Key Competitors

n

Key competitors of the LRE32 include Siemens SIRIUS 3RU and ABB TA25DU. These relays offer similar functionalities but differ in features and usability.

n

n

Comparative Analysis

n

While competitors may offer comparable protection, the LRE32 stands out with its user-friendly interface, compact design, and robust performance. Its ease of programming and reliability make it a preferred choice in many industries.

n

n

Troubleshooting Common Issues

n

Identifying Common Problems

n

-

n

- Overheating: Check for proper ventilation and ensure the current settings are correct.

- Nuisance tripping: Adjust the delay settings and verify the motor’s load conditions.

- Display errors: Reset the relay or update the firmware if necessary.

n

n

n

n

Solutions and Preventive Measures

n

Regular maintenance, including cleaning and inspecting connections, can prevent many common issues. Keeping the firmware up to date also ensures optimal performance.

n

n

Maintenance Tips

n

Routine Maintenance Practices

n

-

n

- Regular inspections: Check the relay and connections periodically for signs of wear or damage.

- Cleaning: Keep the relay and surrounding area free from dust and debris.

- Firmware updates: Ensure the relay’s firmware is current to benefit from the latest features and improvements.

n

n

n

n

Long-Term Care and Upkeep

n

Schedule annual check-ups and calibrations to maintain the relay’s accuracy and reliability. Replacing worn components timely can also extend the relay’s lifespan.

n

n

User Reviews and Feedback

n

Insights from Industry Professionals

n

Professionals appreciate the LRE32 for its reliability and ease of use. Many note that it significantly reduces downtime and maintenance costs.

n

n

Common Praises and Criticisms

n

While the LRE32 is praised for its robust design and user-friendly interface, some users wish for more advanced features like remote monitoring capabilities.

n

n

Future Developments

n

Upcoming Features and Improvements

n

Schneider Electric continuously innovates, and future versions of the LRE32 may include enhanced connectivity options, such as IoT integration for remote monitoring and control.

n

n

Trends in Industrial Automation

n

The trend towards smarter, more connected devices is likely to influence future iterations of the LRE32, making it an even more integral part of industrial automation systems.

n

n

FAQs About Schneider LRE32

n

What is the primary function of the Schneider LRE32?

n

The primary function of the Schneider LRE32 is to protect electric motors from overload and phase failure, ensuring safe and efficient operation.

n

n

How do I program the LRE32?

n

Programming the LRE32 involves using its digital display and buttons to set parameters such as current range and delay times, following the user manual for detailed instructions.

n

n

Can the LRE32 be used in harsh environments?

n

Yes, the LRE32 is designed to operate reliably in harsh industrial environments, with a wide operating temperature range and robust construction.

n

n

What industries commonly use the LRE32?

n

Industries such as manufacturing, mining, and energy commonly use the LRE32 due to its reliability and efficiency in protecting critical machinery.

n

n

How often should the LRE32 be maintained?

n

Routine maintenance should be performed regularly, with detailed inspections and calibrations at least once a year to ensure optimal performance.

n

n

Conclusion

n

The Schneider LRE32 is an essential component in industrial automation, providing reliable protection for electric motors. Its robust design, ease of use, and versatility make it a preferred choice across various industries. Whether you’re installing a new system or upgrading an existing one, the LRE32 offers the efficiency and reliability needed for modern industrial operations.